Education & Certifications

At the Life Cycle Institute, we empower individuals and organizations through training that promotes continuous improvement and delivers measurable results. Our programs are designed by experts in asset management, reliability, and instructional design ensuring that our education is comprehensive, flexible, impactful, and tailored to meet diverse learning styles and operational environments.

Empowering Professionals with Transformative Training

Our training programs focus on asset management, reliability and maintenance program optimization

For over 20 years, the Life Cycle Institute’s training and certification programs have equipped professionals with the skills needed for asset management, reliability and maintenance program optimization. With university-backed certifications and a commitment to transformative learning, we ensure your training investment drives sustainable results.

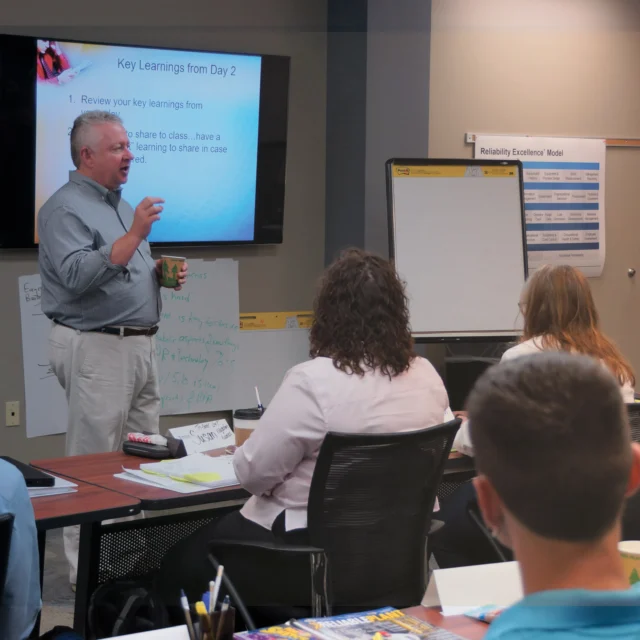

Our public, classroom-based courses deliver transformative learning experiences that combine theory with real-world application

Participants can collaborate in person and virtually with industry peers while enhancing skills in asset management, maintenance, and reliability.

For organizations looking to upskill teams, we offer private training to address specific concerns

These sessions encourage discussion and collaboration around your organization’s unique operational scenarios and goals.

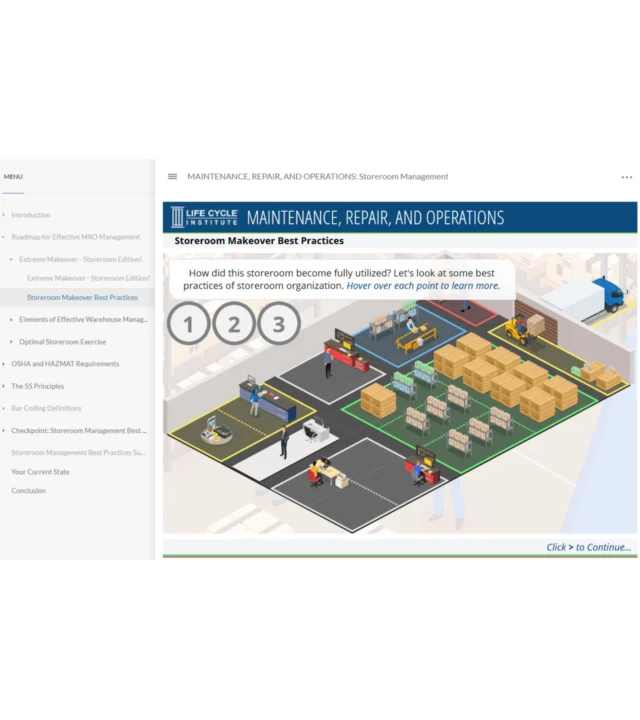

Our interactive eLearning modules are designed to be engaging, practical, and results-focused

Each course is built with real-world scenarios, problem-solving exercises, and action plans that participants can immediately apply in their workplaces.

Our unique 3A Learning Process®—Align, Assimilate, Apply—ensures that training leads to behavior change and measurable business results

By clearly defining learning outcomes, engaging participants in relevant applications, and encouraging practical application in their work environments, we create impactful educational experiences. At the Life Cycle Institute, we call this “High Impact Learning,” and can create a custom program for your organization or team.

Our university-backed certification programs empower professionals to drive organizational excellence

Each program equips participants to deliver measurable business results aligned with industry standards like ISO 55000.

Ready To Optimize Your Operations?

Testimonials

Take the Next Step

Discover how our training can advance your career and lead to significant improvements in your operations.