By integrating training and change management, you can better prepare teams to support business goals in an increasingly digitized manufacturing future

By Tara D. Holwegner, Intellectual Property (IP) Manager at Life Cycle Engineering

As published in Food Industry Executive

Tell me if this sounds familiar. You identify a new tool or system to address an organizational pain point. After a significant technological investment, it doesn’t produce the results you wanted and you scrap it….wasting both time and money.

When we fail to cultivate a successful ecosystem that connects humans and technology we let down our most valuable assets – our people. If your goal is to be a more technologically driven workplace, you need new ways of working. This means preparing your workers for a shift in “traditional” roles and disciplines. Equipping your teams with the right skills in order to harness technological advancements will help drive efficiency and data-driven decision-making. What you need is a smart culture – and it starts with organizational engagement, new procedures, better education, and training your workforce.

You may say, “Well, I already invest in training my teams.” That could be true, but how are those employees applying that knowledge? Do you know what your ROI is? Many organizations struggle to move the knowledge gained in training from the classroom to the workplace. The good news is that with some preparation and planning, your team can uncover opportunities to leverage technology.

We struggled with these same challenges and developed the 3A Learning® process to help our customers and teams integrate the science of learning and the discipline of change management. The first step of the 3A process is to Align, or establish learning objectives and goals linked to performance, followed by the Assimilate phase – choosing the right learning to meet your needs and budget. The next phase is Apply – after applying the training, it’s about ensuring the right support and online tools are in place. Bonus: these items can be managed as high or low-tech as you’d like.

Align: Consider the forecast for a shift in skill needs

In order to ensure a “smarter” tomorrow, there is a critical need for upskilling. In addition to becoming more comfortable and gaining more “digital acumen,” manufacturing and industrial jobs will see soft skills becoming just as important as technical ones. As technology such as AI reduces the need for manual labor, workers are presented with big opportunities for upskilling, allowing employees to be more productive and strategic in their roles, improving their quality of work and becoming more efficient in their decision-making.

The research trends are compelling to plan for both upskilling (improving current skill set) and reskilling (focusing on learning new skills):

- Without making changes to the skills composition of the workforce, manufacturers could leave up to 2.1 million jobs unfilled between 2020 and 2030, impacting everything from productivity to innovation and competitiveness to GDP (Deloitte 2021)

- McKinsey research projects that by 2030, the share of physical and manual tasks in the overall economy will have fallen by about 27 percent since 2016, replaced by greatly increased demand for technological and cognitive skills (McKinsey 2022)

As industry trends influence changes over time, organizational changes and new program initiatives – like maintenance and reliability improvement efforts – can also shift roles in terms of upskilling and reskilling needs. For example, you may have a Maintenance Planner/Scheduler position that, in addition to gaining digital acumen by using a new CMMS system, can and should begin to use the information in reports to identify continuous improvement opportunities and analyze data. Supervisors can move away from reactionary minute-to-minute work execution problem-solving to proactive loss elimination. Shifts in focus like these can mean that each role is poised to bring new benefits to the business.

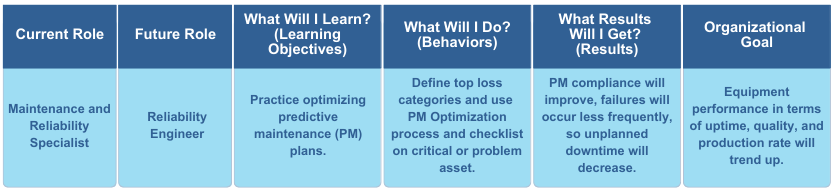

A learning impact map can align learning needs, on-the-job action and business results. This learning impact map can be put into an online learning management system to help track and manage results.

The supervisor/manager and learner should discuss and agree on the learning impact map objectives and goals so that proper training and development planning can occur.

The supervisor/manager and learner should discuss and agree on the learning impact map objectives and goals so that proper training and development planning can occur.

A few best practices you should follow when using learning impact maps:

- Only 2-3 goals should be documented in the map

- Goals should be able to be worked on within 30 days of the learning event

- Develop goals that will be able to produce or see some results within 90 days

These timeframes are recommended so the learner is motivated by success, and so that the business results achieved can be directly tied to the training or development opportunities they received.

Assimilate: Select the right learning to meet your needs and budget

Once you’ve targeted your learning objectives, you can start planning how to reach those educational needs. Today there are more quality options than ever to reach your learners.

In-person or live, virtual classes are good for sharing between learners and having real-time subject matter expert discourse without distractions at the workplace. eLearning or self-paced online courses can be completed at the learner’s own pace and can offer opportunity for immediate application and experimentation on-the-job. Another benefit to eLearning is that it can be used to educate cross-sections of the enterprise and achieve a knowledge base and common language around reliability and asset management.

When implementing a new process, don’t forget to train people how to use it. Here is some advice to consider:

- Make room for application – this means transferring learning from the online or in-person classroom to the workplace (the “what will I do?” section of the learning impact map).

- Have a method to capture or report on results delivered from actions taken after training. This isn’t only to celebrate the success of the learner, but to realize the return on your training investment.

One person really can make a difference. For example, by completing a Life Cycle Institute Reliability Engineering Certification program work product, three individuals produced the following results with a learning investment of roughly $10,000:

- Eliminated a chronic failure that reduced line downtime by 44%, saving $17,520/month

- Implemented a new PM inspection to reduce unscheduled downtime by 67%, saving $130K annually

- Established PdM tasks to increase line OEE by 1.6%, potentially saving $1M annually

How much are you willing to invest in one person to get these types of results?

Apply: After the training – now what? Application, support, and online tools

So…we’ve selected the people, defined learning objectives, invested in a training or certification program, and have documented what we’re hoping our people will DO with that new knowledge and skills after the training.

Now what? The application phase is all about moving from the classroom to the workplace.

Here are a few suggestions on how to follow through on learning impact maps:

- Review the learning impact map activities and goals bi-weekly with your learners for 90 days.

- Ask them about their progress toward their goals.

- The learner should be expected to begin trying the items in the “what will I do” column within 30 days of the training and see some sort of result within 90 days.

If your training program provides “action plans,” string them together into a longer assignment where your learner documents their activities and any results they produce. For example, provide resources for a group to perform a problem-solving event or root cause analysis – and task your learner with running it.

The best way to learn something is to train someone else by having your learners coach others in your team on the new knowledge or skill. You can also embed training and development into professional development cycles. Upskilling and reskilling are not a “one and done” activity – it is an iterative cycle of definition, development, and transition.

3A Learning prepares your teams to support business goals and an increasingly digitized future

When it comes to workforce development, managers are well-positioned to work with leadership to identify the skills and education your people will need to produce the desired results. By using the 3A Learning process, you can establish a world where all your assets – people, equipment, technology and tools – are operating at peak efficiency.

We are in exciting times – “smarter” times – where technology can automate tasks, augmented/virtual reality and artificial intelligence can improve operations, performance monitoring sensors can harvest data, and digital twin blueprinting is the special of the day…the list goes on. But without properly engaging and educating your workforce, applying, AND measuring those skills and training, you’ll never get the results you want. In an increasingly digitized manufacturing industry, a smart culture approach to preparing your teams can help to better support business goals and ensure long-term success for your organization.

Tara D. Holwegner, CPTD, PMP, CMRP, is the Intellectual Property (IP) Manager at Life Cycle Engineering. Tara transforms LCE’s reliability and asset management IP into market-leading products that can accelerate a customer’s ability to meet performance objectives. You can reach Tara at tholwegner@LCE.com.