LCE Equips Navy With Training Needed to Keep Diesel Engines Running

solutions

sectors

LCE Equips Sailors with Diesel Engine Training

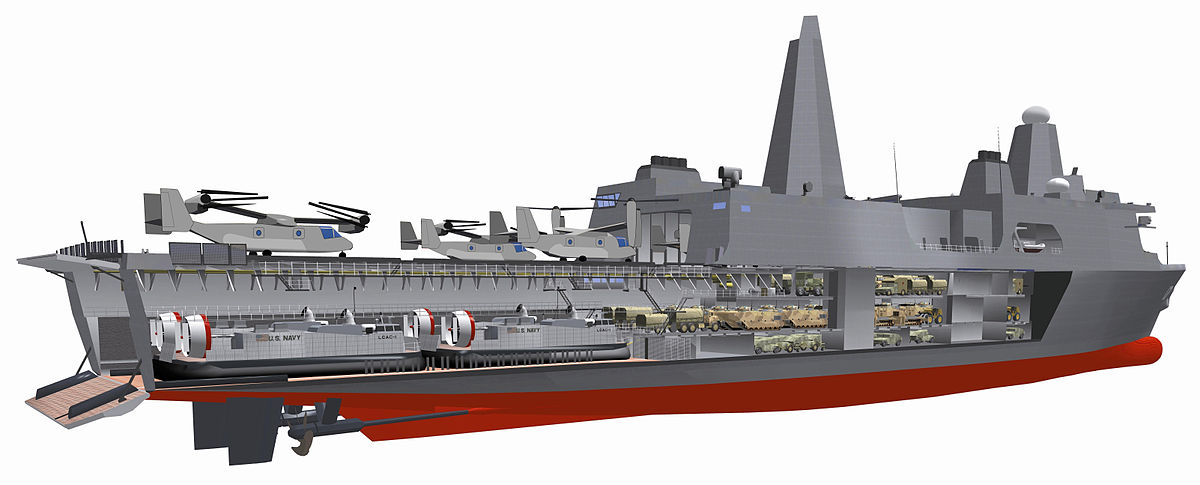

The Propulsion, Power and Auxiliary Machinery Systems Department of the U.S. Navy’s Naval Surface Warfare Center in Philadelphia (NSWCPD) is responsible for all auxiliary systems for surface and undersea vehicle machinery, ship systems, equipment and material. Onboard LPD 17 Class Navy warships, the engineering department is charged with operating, repairing and maintaining the main propulsion diesel engines, ships service diesel engines, electrical distribution plants, auxiliary equipment and other equipment required for the ship’s operation and survival. This tasking is essential to get the ship to any designated area in the world, perform its assigned mission and return home.

A Shortage of Adequately Trained Sailors Threatens Diesel Engine Readiness and LPD 17 Class Ship Availability

LPD 17 Class ships were built without any diesel engine life cycle training in place. This resulted in ships force relying on training from the shipyard during new construction, prior to their acceptance trials and sail-away. As the pre-commissioning sailors transferred to other roles, the initial knowledge base was lost. The lack of sustained life cycle training, coupled with manpower reduction, played a major role in diesel engine readiness and availability of LPD 17 Class Ships.

To remedy the training concerns, the Navy began sending LPD 17 Class sailors to the LSD (41/49) Class MOD 3 Main Propulsion Diesel Engine course at the Recruit Training Command in Great Lakes, IL. However, the controls, design, function and maintenance standards covered in the course differed from those of the LPD 17 Class engines, so sailors learned basic engine operation, but not the platform specifics required to effectively operate and maintain the LPD 17 engines. Compounding the challenge was the fact that the LPD 17 Class ships are the only ships in the Navy built with a split electrical plant configuration, posing another training shortfall for the LPD 17 ships service diesel engines and electrical plant.

U.S. Navy Deploys Multiple Diesel Engine Training Strategies to Address Training Shortfalls and Improve Performance

In 2007 the Navy began a Training Planning Process Methodology (TRPPM) to address the LPD 17 Class training shortfalls. NSWCPD Diesel ISEA Code 421 recommended that the Navy develop, implement and conduct operational training to sailors prior to their sail-away “interim training”. This initiative was created to bridge the gap until life cycle training could be established. Life Cycle Engineering supported NSWCPD in their effort to develop, deliver curricula and provide effective training to the deck-plate engineers so they possessed the skills and knowledge needed to operate and maintain both their diesel engines and their electrical plant while improving the ship’s availability and diesel engine readiness.

Upon completion of the TRPPM process in 2011, the Navy decided to implement additional requirements to ensure training and manning sustainability. The plan required LPD 17 Class ships to maintain nine sailors who have completed four courses covering diesel engine operation. Upon graduation of these courses, sailors would be awarded the LPD 17 Class 4151 Navy Enlisted Classification (NEC). The NEC requirement was implemented in late 2014 with the goal of filling the required positions through schoolhouse life cycle training courses by January 2018. As of July 2018, the 4151 NEC position requirement was 50% filled.

To accommodate the continuing need for effective skills development, Life Cycle Engineering has developed training that blends classroom instruction and shipboard hands-on training. Instructor critiques are conducted at the completion of each course along with student critiques. The critiques are utilized to develop training course metrics and generate feedback from the students. The metric data and feedback is used to ensure that the training is being conducted effectively and continuously improved as well as including any current fleet events and concerns noted by various inspection/training teams or DEIs. The Life Cycle Engineering Training Coordinator and his team continue to train students at the Surface Warfare Officers School in Newport, RI and other shore-based facilities. Life Cycle Engineering also frequently receives requests from operational commands to conduct training onboard their ships.

The NSWCPD Diesel In-Service Engineering Agent has noted a significant improvement in diesel engine readiness and sailor engineering plant operation proficiency between ships that have completed the training and ships that have not. The success of the training program has also been recognized by the Surface Warfare Officers School, which has requested that Life Cycle Engineering conduct this training with their Prospective Engineer/Division Officers and also their Prospective Commanding Officer students.

Life Cycle Engineering has trained more than 480 sailors since December 2010. Even though this training program does not award the 4151 NEC designation to sailors, it does provide the knowledge and skills needed to effectively operate, troubleshoot, repair and maintain their diesel engines. As recognized at Propulsion Engineering Steering Committee events, Life Cycle Engineering’s training program continues to significantly improve diesel engine readiness onboard the U.S. Navy’s LPD 17 Class Ships.

To learn more about LCE’s ongoing naval support,

visit the Integrated Logistics Support web page.