Life Cycle Institute Partners with DTE Energy to Develop and Deliver Training That Helps Build Asset Management Capabilities

solutions

sectors

DTE Energy is a Detroit-based, diversified energy company involved in the development and management of energy-related businesses and services. More than 10,400 DTE employees work in utility and non-utility subsidiaries in more than 26 US states.

As DTE’s business grew, they needed a strategic approach to learning and development across business units. To respond to this need, DTE created organization-wide “foundational capabilities” to drive corporate values, business strategy and goals. Early DTE foundational capabilities included leadership, business acumen, and continuous improvement. After successfully establishing eight foundational capabilities, a senior executive with a background in nuclear energy challenged the company to define a ninth foundational capability for asset maintenance.

Fueled by an executive sponsor with a passion for asset reliability and a business need to use existing assets to accomplish an aggressive five-year vision, DTE’s organizational learning department formed a cross-functional task force. The Asset Management Foundational Capability (AMFC) task force spanned six business units and was chartered to design a foundational competency around physical asset maintenance and to promote it as a core company value. The company had pockets of excellence, and deep experience in reliability spread across its business units but did not have consistent, enterprise-wide asset maintenance processes or training.

DTE was confident that their strategy and plan were sound and they were building excellent documentation for the technical side of their implementation. However, both the task force and DTE’s organizational learning department faced bandwidth issues and lacked availability to build and deliver the initial awareness education and messaging critical to AMFC success. For this reason, DTE decided to partner with Life Cycle Institute to build and deliver the training, as well as general oversight on DTE’s approach to proactive maintenance. Partnering with Life Cycle Institute allowed DTE to realize the benefits it sought when the AMFC task force initially determined the project approach.

Life Cycle Institute custom-developed content to align with DTE’s development of Asset Management Foundational Capabilities. To begin the process, Institute Content and Learning Performance SMEs interviewed DTE partners about their objectives for the training and determined what material should be included. The Institute SMEs expertly shaped the content into chunks so it could be effectively delivered by the in-house facilitator.

Life Cycle Institute’s custom course development process includes seven phases:

Phase 1: Design

Phase 2: Develop First Draft

Phase 3: Review First Draft

Phase 4: Develop Second Draft

Phase 5: Review Second Draft

Phase 6: Pilot Final Delivery

Phase 7: Final Delivery

During Phase 2, Institute SMEs built the course and delivered slides, activities, and handouts for the client to review. Phase 3 included a thorough team review of all custom course content and activities. During Phase 4, the Institute SMEs completed any necessary modifications that resulted from the team’s evaluation of the draft. During this phase, the Learning SME delivered the Facilitator Guide and finalized the slides, activities, handouts, and materials checklist. The team assessed the final draft in Phase 5, with an emphasis on the look, feel, flow, and formatting of the content.In Phase 1, (the design phase), Life Cycle Institute determined DTE’s target audience, learning objectives, course modules and activities, and established a common language. Institute SMEs built a detailed design for the course and ensured DTE was satisfied before diving into additional course development. The design-phase deliverables included a robust course summary with detailed outlines for each day of the class, course description, learning objectives and a comprehensive schedule. The Learning SME also provided content sources, a learning impact map, and module plans including content, activities, and an itemized timeline.

In the Pilot Final phase, course materials were officially ready for pilot delivery. The Institute SMEs then made any necessary adjustments that resulted from the pilot delivery. The final Phase 7 included course delivery and completed versions of the Facilitator Guide, slides, activities, handouts, and materials checklist.

Life Cycle Institute developed two levels of instructor-led, classroom training based on the AMFC model. One curriculum was for practitioners and one for non-practitioners. The practitioner workshop lasted two-and-a-half days and spent three to four hours on each capability. The one-day, non-practitioner course was derived from the practitioner course and included a hands-on application session with business units within DTE.

Originally, DTE requested a train-the-trainer approach, in which Life Cycle Institute would create the content and train an in-house DTE facilitator. However, after Life Cycle Institute delivered the course pilots using its A3 Learning and active learning facilitation style, LCI was asked to deliver the subsequent workshops as well. In addition to ensuring the quality of course delivery, DTE recognized the value in partnering with external experts to add credibility to the program.

The Institute delivered the following custom courses for the practitioner workshop:

- Effective Leadership and Work Culture for Asset Maintenance and Reliability

- Establish Asset Maintenance and Reliability Strategies

- Effective Work Management for Asset Maintenance and Reliability

- Monitoring and Reporting Asset Condition and Performance

- Applied Continuous Improvement for Asset Maintenance and Reliability

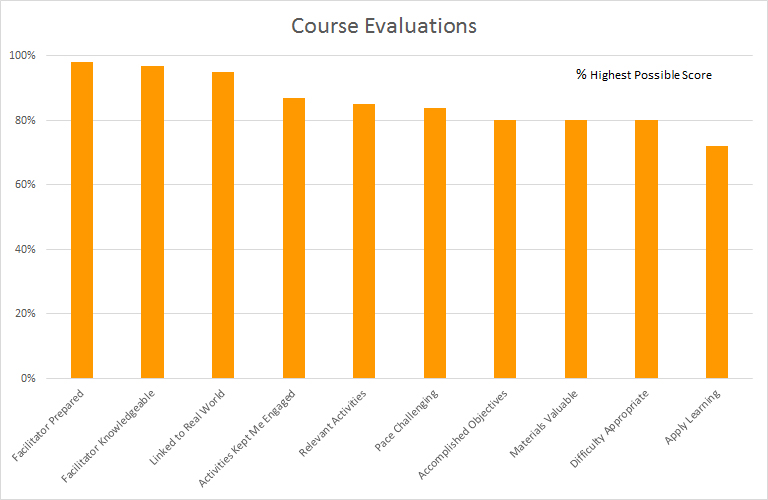

Evaluation scores from the training were impressive, with well over 75% of participants giving the course the highest possible rating, and some evaluation areas saw highest scores above 90%.

DTE reported several benefits of the Institute’s course development and delivery:

- Educated employees on the reliability program and business needs

- Partnering reliability SMEs with learning professionals ensured the education was technically sound, relevant and effective

- Provided time for students to gather and network

- Provided a site or collaborative workspace to sustain the community virtually

Here’s what students had to say about the training delivery:

- “One of the best trainings I’ve had in years. The Program will allow me to take pieces and drive change in my group.”

- “Many down to earth examples throughout the training made the learning easier.”

- “The mixture of all business units at different stages of AM helped to make connections.”

- “The best training I’ve had my 8 years at DTE.”

The AMFC documented several lessons learned to reference in latter project phases as well as in new initiatives. One of those lessons was that partnering learning and reliability professionals on awareness education and messaging is advantageous.

As the implementation continues to progress, the business results the organization receives from adding Asset Maintenance as a DTE Foundational Capability is critical to achieving DTE’s vision of being the best-operated energy company in North America and a force for growth and prosperity in the communities where they live and serve. Life Cycle Institute is proud to have supported the effort with custom course development and delivery best practices.

To learn more, visit the Custom Course Development web page.