Hot Strip Mill Regaining Former Status

Background

In 2017 a major steel company decided to focus on a significant reliability improvement initiative at several of their steelmaking operations. Improvement in reliability was needed in many of the operations. But none were more important than their hot strip mill, which needed to produce the lion’s share of the company’s products.

The operation was the flagship of the company for many years but had suffered due to hard times in the industry. Forced cost reductions had affected their ability to improve and maintain the assets through annual capital investment and limited their attention to proactive maintenance and reliability practices.

The company chose to partner with Life Cycle Engineering to help them with the strategy of implementing reliability best practices while they also invested heavily in equipment upgrades. This strategy is now delivering positive results in many of their operations. One of the most significant improvements has been in their hot strip mill.

The Journey Begins with Education

The first step in the journey was to educate the executive team on the importance of reliability best practices and the team’s role in the effort. The executive team spent an entire day understanding how reliable operations could give them a competitive advantage. The next step was to assess their current state of reliability. A Reliability Excellence Assessment was performed at several of their operations including the hot strip mill. The hot strip mill assessment results indicated that they were reactive; they were utilizing some proactive tools, but the performance of the mill was inconsistent due to the unreliability of the equipment. The reliability assessment pointed out that focus was needed in the areas of Reliability Leadership, Culture Change, Work Management, and Reliability Engineering.

Reliability Leadership and Culture Change

To create the necessary foundation for implementing new approaches and new processes, LCE delivered a Reliability Excellence for Managers course. All of the hot strip mill managers attended four, three-day sessions over a one-year period. The LCE Leadership and Change expert provided one-on-one coaching to reinforce what managers had learned during each class. At the same time, a leadership team was formed to govern the reliability improvement initiative. This team developed communication plans, governing principles, and performance measures to track progress and, most importantly, managed the organizational change from a reactive to a proactive culture. The goal was to equip managers to create the necessary level of active sponsorship for the improvement effort, lead plant employees through the painful aspects of organizational change, and work through the typical resistance to change. Partnership agreements between Operations and Maintenance were developed that defined how the organization would work together to improve the reliability of the hot strip mill.

Work Management

As mentioned earlier, one of the areas needing improvement was how maintenance work was managed. The hot strip mill’s efforts to improve work management focused on the entire process of how work was identified, approved, prioritized, planned, scheduled, and executed. Considerable focus was placed on how work was being planned and scheduled as well as how to increase the utilization of the entire workforce. Planners and Supervisors attended LCE’s four-day Maintenance Planning and Scheduling course, followed by one-on-one coaching by LCE’s Work Management expert. To make the improvements in work management, a cross-functional team was formed to review their work management processes. An LCE Work Management expert led them through an exercise of identifying and closing gaps in those work management processes. Leaders and plant personnel were trained on the processes, and coaching cards were used to help managers and supervisors reinforce proactive behaviors. Weekly scheduling meetings became joint sessions between Operations and Maintenance that ensured that the right work was being done effectively and efficiently. Preventive maintenance and schedule compliance measures were shared by both parts of the organization. This was a turning point in the culture change and created positive movement in their performance measures.

Reliability Engineering

The Reliability Engineering effort at the hot strip mill began with using LCE’s equipment criticality tool to identify the critical equipment. The next step was to compare that knowledge with delay analysis information so that their Reliability Engineers could identify bad actors and focus their efforts appropriately. The Reliability Engineers attended LCE’s four Reliability Engineering classes on Risk Based Asset Management, Reliability Engineering Excellence, Predictive Maintenance Strategy and Root Cause Analysis, followed by one-on-one coaching by LCE’s Reliability Engineering expert on how to apply what they had learned. This led to the development of equipment maintenance strategies that optimized their preventive and predictive maintenance program and contributed to a reduction in maintenance delays.

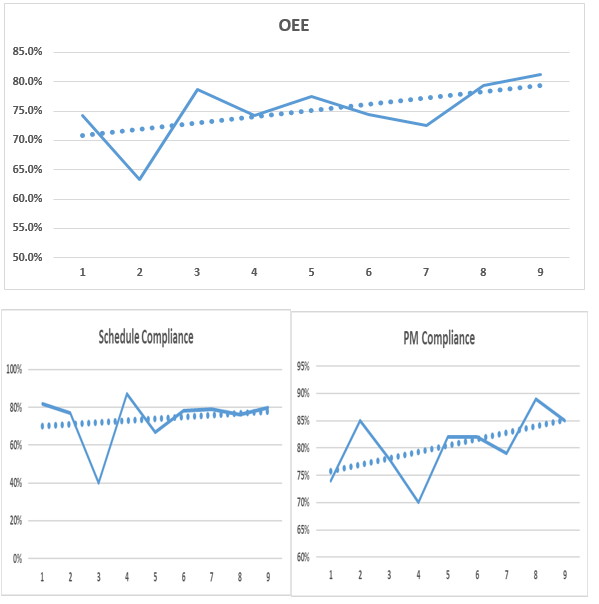

These combined efforts, along with some equipment, have put the hot strip mill back on track to regain the flagship status it once enjoyed. The mill is now better prepared to maintain the new equipment as well as the old. Figure 1 shows how several key measures, including PM and schedule compliance, steadily improved in 2019. These improvements through the third quarter of 2019 have yielded an OEE improvement from 74% to 81%. Their goal in 2020 is 85%. They are definitely trending in the right direction.

Conclusion

Reliability improvement journeys require educating the entire organization, giving people the ability to apply the knowledge, and reinforcing proactive behaviors. The technical side of the solution is the easy part compared to the tenacity it requires to change the culture. The latter can be a multi-year effort with tremendous dividends, as illustrated in this case study.